Advanced welding machines are essential tools in modern industrial processes, where efficiency, durability, and precision are paramount. When selecting the right welding machine for industrial use, several factors must be considered to ensure it meets the rigorous demands of large-scale production environments. While power and performance are crucial, factors like reliability, ease of maintenance, and adaptability to different materials are equally important. In this article, we will explore the key features to look for in industrial welding machines designed for heavy-duty applications.

Power and Performance of Industrial Welding Machines

When selecting industrial welding machines, power output is one of the most critical factors. High-performance machines must handle various materials, from thin sheets to thick metals, without compromising the quality of the weld. These machines need to offer adjustable power settings, allowing for versatility across different welding tasks. In industrial applications, welding machines must deliver enough power to penetrate thicker materials while maintaining high weld quality. At the same time, the ability to reduce power for more delicate jobs, such as welding thinner materials, helps avoid damage.

Consistency in performance is another key consideration. The best industrial welding machines provide stable arc throughout the welding process, ensuring smooth, defect-free welds. A stable arc also minimises spatter, making the welding process more efficient and reducing the need for post-weld clean-up.

Durability and Maintenance of Industrial Welding Machines

Durability is essential for industrial welding machines used in harsh working environments. These machines must withstand extreme temperatures, dust, and continuous operation without frequent breakdowns. Machines built with high-quality components are more likely to endure heavy use, reducing downtime due to repairs and extending the equipment’s lifespan.

Ease of maintenance is another critical feature. Industrial welding machines should be designed for quick and simple maintenance procedures. Features like easy replacement system for consumables, accessible internal components, and diagnostic systems that alert users to potential issues help keep machines running efficiently. Minimising repair time ensures that production lines remain active, improving overall productivity.

Versatility and Adaptability in Industrial Welding Machines

Versatility is a key feature in industrial welding machines, especially in environments where multiple types of materials, such as steel, aluminum, and stainless steel, need to be welded. The ability to adjust the machine for different materials and support a range of welding processes (such as MIG, TIG, or Stick welding) is crucial in industrial applications.

Whether the task involves a straightforward structural weld or a complex fabrication, having a machine that can easily switch between welding methods streamlines the production process. This adaptability reduces the need for multiple machines, saving both space and costs while increasing operational efficiency.

Automation and Advanced Features in Industrial Welding Machines

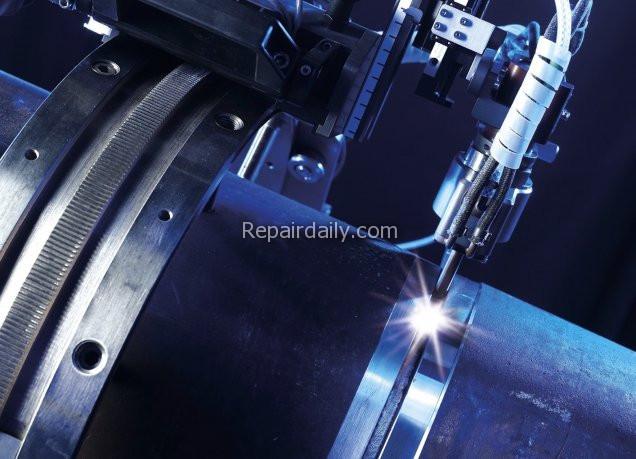

With the shift towards automation in industrial welding, it is increasingly important to choose welding machines with automated features. Machines with programmable settings and digital interfaces allow operators to control welding parameters with precision, resulting in more consistent and higher-quality welds with less manual intervention.

Advanced technologies like pulse welding help control heat input, which improves weld quality, particularly on thinner materials. Many industrial welding machines come with pre-programmed settings for specific materials or tasks, making it easier to achieve optimal results. This also helps operators with varying levels of expertise get high-quality welds, as the machine assists in setting the correct parameters.

Welding Data Control in Industrial Welding Machines

In the realm of Industry 4.0, effective welding control is crucial for enhancing both quality and efficiency in industrial applications. Modern welding machines are increasingly equipped with advanced data collection and analysis systems that enable welders to monitor and optimise their processes in real-time. By saving welding parameters to USB drives or utilising cloud-based platforms, operators can access and visualize critical welding data anytime, anywhere, streamlining decision-making and ensuring quality assurance.

Key solutions, such as wireless connectivity to welding machines, empower users to make adjustments on the go via smartphone applications that connect through Bluetooth technology. These innovations not only enhance control over welding operations but also facilitate seamless integration into automated production environments, ensuring that manufacturers can meet the growing demands for precision and consistency in their welding tasks.

Safety Features in Industrial Welding Machines

Safety is paramount in industrial settings, and industrial welding machines should be equipped with robust safety features to protect operators from potential hazards such as overheating, electrical surges, or gas leaks. Essential safety mechanisms include automatic shut-off, thermal overload protection, and gas leak detectors. These features help prevent accidents and ensure a safer working environment.

Additionally, ergonomic designs improve operator comfort, reducing fatigue during long hours of work. Machines that are lightweight, well-balanced, and have user-friendly control panels make operation easier and safer, reducing the chances of errors caused by operator fatigue.