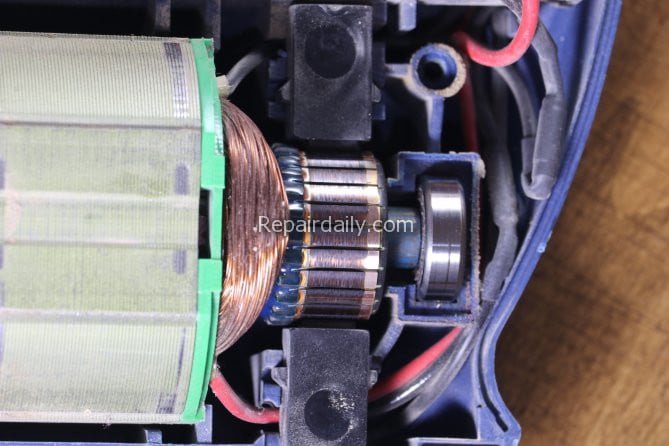

A carbon brush is an electrical contact that conducts current flow between an engine’s wires and moving parts, frequently found in rotating shafts. DC motors use carbon brushes to ensure a smooth transfer of electricity from the outside to the center of the motor. Standard engines such as appliances, power tools, and generators use carbon brushes.

Initially, people used standard wire brushes. However, many found that these wire brushes tended to wear away the commutator, causing problems in the motor. Due to its self-lubricating properties, carbon was used, which caused minor wear in the commutator compared to harder metals. Nowadays, carbon brushes are used widely due to being excellent conductors.

Reasons Why A Carbon Brush Replacement Is Necessary

Carbon brushes, like any other engine component, must be replaced. When the carbon brush wears out, the motor may spark, and a broken electrical contact may result in a lack of electricity in all parts of the engine. When this happens, removing dirt can stop carbon brushes from sparking. Some of the most common reasons for carbon brush failure include:

- Improper installation of the carbon brush or use of the incorrect size

- Carbon brush damage caused by underloading or overloading the brush

- Voltage surges can also cause problems.

- Issues with the commutator

Fortunately, you can replace carbon brushes yourself. Carbon brushes aren’t expensive and you don’t need to be a motor or engine expert to replace them. However, to function correctly and smoothly, you must remember some tips when replacing carbon brushes.

When To Replace A Carbon Brush

It’s critical to understand when to replace your carbon brush. Watch the carbon until about a quarter-inch wears out due to use to test this. It’s the appropriate time to replace these brushes. Replacement should occur immediately if the carbon brush shows signs of breakage, crumbling, or burning. A change in the color of the spring, such as rainbow patterns, is another sign that replacement is needed, as this could indicate a broken lead. If the spring collapses, it shows that you should install a replacement. Many blogs and websites can give you tips on when to replace your carbon brush.

1. Identifying the Grade of Carbon Brush Required

Four carbon brush grades are available, varying in the type of carbon used and other ingredients included. You must know the appropriate grade to use for your carbon brush replacement to avoid problems with the motor.

- Carbon Graphite

Carbon graphite brushes are the predecessors of modern-day brushes. You can find them in motors that are usually older and slower. These carbon graphite materials have high strength but are only limited to lower densities. Carbon graphite brush grades are unsuitable for today’s commutators that generate high friction.

- Graphite Carbon Brush

This carbon brush’s composition is resin-bonded graphite. These graphite brushes are great for controlled filming and riding on commutators. Graphite brushes have fast filming properties, which protect the commutator during operation, particularly in contaminated environments. This quality allows for lower absorption and higher density, which are beneficial in reducing commutator threading.

- Metal Graphite Carbon Brushes

Natural graphite and fine metal powders make up these carbon brushes. Carbon, silver, tin, and lead are the most integral components. Because of the metal’s low resistivity, this makes it more ideal. Found commonly on plating generators with commutators that require low voltage and high brush densities. This carbon brush’s low contact drop is also why people use it on grounding brushes.

- Electrographite Carbon Brushes

The raw materials in the making process of these brushes allow electrographite carbon motor brushes to be the best type of brush for strength and density. It’s better than commuting, operating at high temperatures or low humidity, resulting in a longer carbon brush life. Some treatments can allow electrographite brushes to function in other well-contaminated settings.

2. Finding the Carbon Brush Design Needed

Different motors require different types of carbon brushes. Before buying a carbon brush replacement for your DIY repair, you should identify your engine needs.

- One-Piece Carbon Brushes

This design is the most basic carbon brush type, requiring no electrical or mechanical factors.

- Fractional Horsepower Brushes

A spring is connected and used to load the carbon into its brush holder.

- Split Carbon Brushes

Two, three, or more carbon brushes can be sectored together to form a carbon brush ideal for electrical and mechanical contact. This method of brush separation allows for more electrical connection and evenly distributed riding capacity on the commutator. These carbons are usually glued to a hard rubber top and are held together by a riveted clip.

3. Right Carbon Size for Your Carbon Brush Replacement

Knowing what carbon brush size you need for your motor is essential in the DIY repair of your project. The thickness, length, and width identify these sizes. The size of the carbon brush is critical for the commutator to fit and function properly. The measurement of the length of a beveled meeting is on the longer side. You should include the head in the measuring for those with the head on the top of the brush.

4. Bedding In and Fitting Carbon Brushes

Bedding in is usually not necessary for new carbon brushes. However, for some motors that require brush replacement, fitting and bedding are needed to ensure that the entire area makes contact with the commutator and conducts properly. The most common method is to use a brush bedding stone to grind the edges of the carbon brush to obtain a perfect radius and contact face. Ensure that you thoroughly clean the carbon brush afterward to avoid sediments settling in the commutator and the machine. Remember that carbon brush replacement doesn’t require bedding in or fitting; only perform this procedure when necessary.

5. Remember Not to Grease Carbon Brush

A carbon brush must be connected to the commutator to conduct the electricity required to power the motor. Remember not to grease the carbon brush because it’ll lose contact with the commutator. Because carbon is self-lubricating, the addition of grease is unnecessary. A carbon brush must be connected to the commutator to conduct the electricity required to power the motor.

Conclusion

Replacing your carbon brush is simple and can be done by anyone. Still, there are some things you should know first to avoid problems with the carbon brush, commutator, and motor itself. Most importantly, keep your carbon brush in good working order to ensure that your engine runs smoothly.

I'm so excited to tackle all my home improvement projects! From plumbing to DIY and cleaning - I'm ready to get down to work! #homerepair #homecleaning #plumbing #diy #fixerupper #realestate #renovation #interiordesign #farmhouse #diy #homedecor #hgtv #home #farmhousedecor #modernfarmhouse #farmhousestyle #fixerupperstyle #fixandflip #homerenovation #realestateinvesting #beforeandafter #homesweethome #remodel #realestateinvestor #interior #realtor #joannagaines #flippinghouses #countryliving #design #homedesign #farmhouseinspired #investmentproperty #bhghome #renovationproject #farmhousekitchen #homeimprovement #farmhouseliving #cottagestyle #decor #realestateagent #magnoliahome #homeinspo #magnoliamarket #kitchendesign #dreamhome #shiplap #construction #houseflipping #investor #farmhousedesign #architecture #farmhousechic #homereno #rusticdecor #reno #kitchenremodel #webuyhouses #magnoliatable #rentalproperty #fixerupperinspired #newhome #interiors #homeremodel